Product Description

Key attributes

Other attributes

Applicable Industries

Manufacturing Plant, Machinery Repair Shops, Energy & Mining

Weight (KG)

1650

Showroom Location

None

Video outgoing-inspection

Provided

Machinery Test Report

Provided

Marketing Type

Hot Product 2571

Warranty of core components

1 Year

Core Components

Gear

Place of CHINAMFG

ZheJiang , China

Condition

New

Warranty

1.5 years

Shape

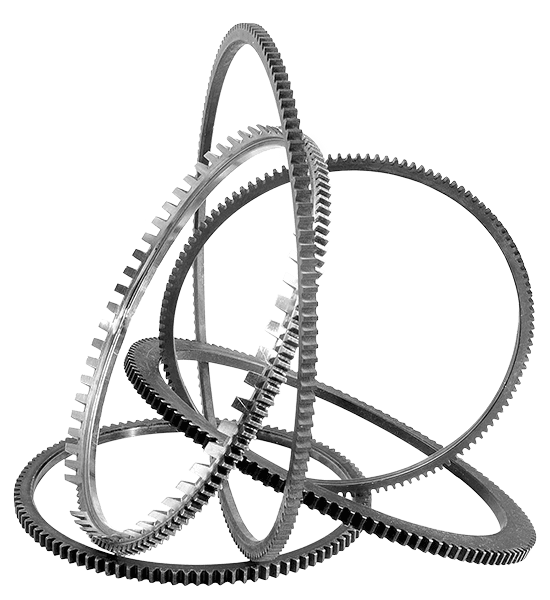

Ring Gear

Standard or Nonstandard

Nonstandard

Tooth Profile

Spur

Material

Steel

Processing

Casting

Pressure Angle

20°

Brand Name

HangZhou

Product Name

custom large diameter alloy steel spur casting large ring gear

Application

Cement kiln

Gear Machining

Gear milling

Module of Gear:

8-120

OD For Gear Wheel:

MAX.13 000 mm

Height For CHINAMFG

MAX. 1200 mm

Certificate

ISO 9001:2015

Tolerance

+/-0.01mm

Heat treatment

QT

Surface Treatment

Surface Hardening or Carburizing and Quenching

Packaging and delivery

Packaging Details

Package for Cement kiln custom large diameter ring gear transmission alloy steel spur casting large ring gear is wooden box and adapts to CHINAMFG transport

Port

ZheJiang ,HangZhou or Others

Supply Ability

Supply Ability

9000 Ton/Tons per Year

OUR WORKSHOPS

OUR EQUIPMENTS

Technology Process

|

Material |

Carbon steel,Alloy steel |

||

|

Structure |

Forging,casting |

||

|

Type of gear |

spur gear,helical gear,Planetary Gear |

||

|

Heat treatment |

Quenching and tempering |

||

|

Process |

forging, rough machining, QT, finish machining |

||

|

Main equipments |

hobbing,CNC machine |

||

|

Module |

up to 200 |

||

|

Precision of gear |

Grinding ISO Grade 5-7 & Hobbing ISO Grade 8-9 |

||

|

Inspection |

Raw material inspection, UT,physical property test,dimension inspect |

||

|

Application |

Mining machinery, mill, kiln and other equipment |

||

OUR CERTIFICATE

OUR CUSTOMER FEEDBACK

CONTACT

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industry |

|---|---|

| Hardness: | Hb190-Hb300 |

| Gear Position: | External Gear |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do ring gears contribute to power transmission?

Ring gears play a significant role in power transmission within mechanical systems. Here’s a detailed explanation of how ring gears contribute to power transmission:

- Torque Transfer: Ring gears are designed with teeth on their outer or inner circumference, depending on whether they are external or internal ring gears. These teeth mesh with the teeth of other gears, such as pinion gears or planetary gears. As the driving gear rotates, the meshing teeth engage with the ring gear’s teeth, transmitting torque from the driving gear to the ring gear. This torque transfer enables the ring gear to rotate and transmit power to other components or systems connected to it.

- Rotational Motion: Ring gears convert the rotational motion of the driving gear into rotational motion of the ring gear itself. The teeth on the ring gear provide a positive engagement with the teeth of the driving gear, ensuring a synchronized rotation. As the driving gear rotates, the meshing teeth push against the ring gear’s teeth, causing it to rotate in the same direction and at a proportional speed determined by the gear ratio. This rotational motion is crucial for transmitting power to different parts of the system or driving various mechanisms and components.

- Speed Reduction or Increase: Ring gears, in conjunction with other gears in the system, can be used to achieve speed reduction or increase. By varying the sizes of the driving gear, the ring gear, and other intermediate gears, different gear ratios can be achieved. When the driving gear is smaller than the ring gear, the ring gear rotates at a slower speed than the driving gear, resulting in speed reduction. Conversely, if the driving gear is larger, the ring gear rotates at a faster speed, leading to speed increase. This ability to control gear ratios allows for power transmission at desired speeds and enables systems to meet specific operational requirements.

- Load Distribution: Ring gears distribute the transmitted loads across their circumference. The teeth of the ring gear engage with multiple teeth of other gears, ensuring that the load is shared among these meshing points. This load distribution helps prevent localized stress concentrations and excessive wear on specific gear teeth. By distributing the load, ring gears contribute to the overall durability and longevity of the gear system, allowing for reliable power transmission even under demanding conditions.

- Compact and Efficient Design: Ring gears offer a compact and efficient design for power transmission. Their annular shape allows for a high gear ratio within a small space, making them ideal for applications where space is limited. Additionally, ring gears can be integrated into various gear configurations, such as planetary gear systems or gearboxes, which further enhance their power transmission capabilities. This compact and efficient design contributes to overall system efficiency and performance.

Overall, ring gears are essential components in power transmission systems. Through torque transfer, rotational motion, speed control, load distribution, and their compact design, ring gears enable efficient and reliable power transmission in a wide range of mechanical applications.

Can you provide examples of machinery that use ring gears?

Machinery in various industries utilize ring gears for different applications. Here are some examples of machinery that commonly use ring gears:

- Automotive Transmissions: Ring gears are an integral part of automotive transmissions. They are used in automatic transmissions, manual transmissions, and dual-clutch transmissions. Ring gears help transmit power from the engine to the wheels by engaging with the pinion gear or other associated gears.

- Industrial Gearboxes: Ring gears are extensively used in industrial gearboxes, which are employed in a wide range of applications. Gearboxes in industries such as manufacturing, mining, construction, and energy generation use ring gears to transmit power and control rotational speed. They provide torque multiplication and speed reduction or increase as required by the specific machinery.

- Wind Turbines: Ring gears are crucial components in wind turbines. They are used in the main gearbox to convert the rotational motion of the wind turbine blades into electrical power. The ring gear connects the rotor shaft to the generator, enabling the transmission and conversion of the mechanical energy into electrical energy.

- Rotary Tables: Rotary tables are used in machining operations to provide precise positioning and rotational movement. They are commonly found in milling machines, drilling machines, and machining centers. Ring gears are employed in the rotary tables to enable smooth and accurate rotation, allowing for precise machining and indexing of workpieces.

- Printing Presses: Printing presses, particularly those used for high-speed commercial printing, often incorporate ring gears. Ring gears help drive the paper feed mechanisms and synchronize the movement of various components, ensuring precise control and alignment during the printing process.

- Excavators and Earthmoving Equipment: Large construction machinery, such as excavators and earthmoving equipment, rely on ring gears for their hydraulic systems. Ring gears enable the rotation and control of the excavator’s superstructure, including the boom, arm, and bucket. They provide the necessary power and torque for efficient digging, lifting, and material handling.

- Conveyor Systems: Ring gears are utilized in conveyor systems, which are widely used in industries for material handling and transportation. They are often employed in large-scale conveyors to drive the pulleys and facilitate the movement of heavy loads along the conveyor belts. Ring gears ensure smooth and reliable operation of the conveyor systems.

- Robotics and Automation: Ring gears find applications in robotics and automation systems. They are used in robotic arms and joints to enable precise and controlled movement. Ring gears provide the necessary torque and rotational capabilities for various robotic applications, including assembly, pick-and-place operations, and material manipulation.

These examples represent just a few of the many machinery and equipment types that utilize ring gears. The versatility and reliability of ring gears make them essential components in various industries, where they play a crucial role in transmitting power, controlling movement, and ensuring efficient operation of machinery.

Can you explain the concept of meshing with a ring gear?

Meshing with a ring gear refers to the process of engaging and interlocking the teeth of a gear with the internal teeth of a ring gear. It is a fundamental concept in gear systems where the rotation and torque transfer occur between two gears. Here’s a detailed explanation of the concept of meshing with a ring gear:

When two gears come into contact and their teeth interlock, they are said to be meshing. In the case of a ring gear, the meshing occurs when the teeth of an external gear, such as a pinion gear, engage with the internal teeth of the ring gear. The teeth of the pinion gear fit precisely between the teeth of the ring gear, creating a mechanical connection.

The process of meshing involves several important considerations:

- Tooth Engagement: Proper tooth engagement is crucial for efficient and smooth meshing. The teeth of the gears must align correctly to ensure a proper fit. This alignment ensures that the teeth make contact at the correct pitch point and maintain a consistent mesh throughout the gear rotation.

- Tooth Profile: The tooth profile, such as the shape and size of the teeth, is designed to facilitate smooth meshing. The profile ensures that the teeth slide smoothly against each other without excessive friction, noise, or wear. The tooth profile also affects the load distribution, torque transmission, and overall performance of the gear system.

- Lubrication: Lubrication plays a crucial role in the meshing process. It helps reduce friction and wear between the teeth, ensuring smooth operation and preventing damage to the gears. Proper lubrication also helps dissipate heat generated during meshing, improving the overall efficiency and reliability of the gear system.

- Clearance and Backlash: Clearance and backlash are important considerations in gear meshing. Clearance refers to the space between the tips of the teeth of the external gear and the root of the teeth of the ring gear. Backlash is the amount of play or movement between the engaged teeth. Proper clearance and backlash are necessary to prevent interference, ensure smooth rotation, and accommodate any misalignment or thermal expansion that may occur during operation.

The quality of the meshing directly affects the performance, efficiency, and reliability of the gear system. Proper design, manufacturing precision, and maintenance practices are essential to achieve optimal meshing between gears, including ring gears.

It’s important to note that the specific parameters and requirements for meshing, such as tooth geometry, clearance, backlash, and lubrication, may vary depending on the application, gear type, and operating conditions.

editor by CX 2024-04-15