Product Description

Production capacity

| Design: | We use the most advanced mould design software Auto CAD, Pro/E, Solidworks, UG (dwg, dxf, IGS, STP, X-T) |

| Manufacture: | We use advanced technology, unmatched skill, professional and advanced equipment size range from 15T-10000T, and experienced technicians to fit our customers requirements, like tooling manufacturing,robot welding,forging, steel casting, stamping and surface treatment service |

| Process and Capability: | Cnc machining, Casting,Forging,Progression die, Stamping, Metal Deep drawn, Bending, Punching, Threading, Welding, Tapping, Riveting, Grinding, Laser cutting,Metal Fabrication,forming,spinning, CNC Punching, Plasma cutting, Goffered, Stretch forming ,Tig/Mig Welding,Assembling, Shearing, Blanking, CNC Bending…………, |

| Price Terms: | Fob HangZhou or ZheJiang or any other port in CHINA |

| Lead time: | 20-50days based on the different products |

| Packaging: | Wooden package and canton case or as per customers’ requirement |

| Certification: | ISO9001:2018 , SGS , TS16949,API 8C |

| Industry: | these parts are used in hydraulic presses, press line automation and die handling equipment,Automotive, Electrical, Building, Furniture, Machine assembly, Computer, Air industry , Oil field Equipments, Marine equipments, Mine equipment,Agricultural Machines,Transportation Equipments, OEM/ODM Electronics…… |

Company advantage

ZheJiang Kaiye Heavy Industry Co., Ltd. is located in HangZhou City,is a professional forging enterprise with more than 20 years of forging experience. It has advanced forging equipment, including ring rolling machines, 1000T hydraulic presses, 750kg forging hammers, 1T air hammers, 2T, 3T, 10T hydraulic forging hammers, etc. It can produce various types of forgings from 10kg to 10 tons. Whether it is free forging or simple die forging products, the company can meet the requirements for forgings of various shapes.In addition, the company is also equipped with several heat treatment furnaces (equipment) to ensure that forgings meet their performance requirements after heat treatment.

Equipments

Our Forging equipments:

Our Inspect Equipments:

Our Workshop

Forged Range:

Shape of Forging:

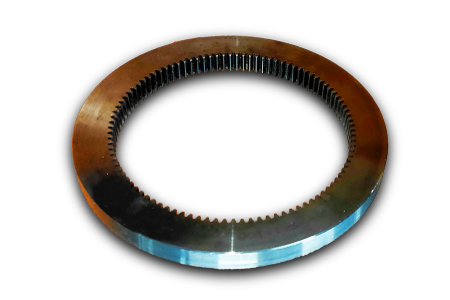

Forged ring, Forged shaft, Forged gear, Forged block, Forged Cylinder, Forged Tube, Forged Sleeve,Forged flange

Material of Forging:

Carbon Steel, Alloy steel, Stainless steel, Titanium steel, Spring steel, Aluminium, Copper, Tool steel.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Processing Object: | Metal |

|---|---|

| Molding Style: | Forging |

| Molding Technics: | Pressure Casting |

| Application: | Machinery Parts |

| Material: | Steel |

| Heat Treatment: | Quenching |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there different types of ring gears available?

Yes, there are different types of ring gears available to suit various applications and functional requirements. Here’s a detailed explanation of the different types of ring gears:

- External Ring Gears: External ring gears, also known as external annular gears, have teeth on the outer circumference of the gear. These gears mesh with an internal gear or a pinion gear. External ring gears are commonly used in applications where the gear rotation needs to be transferred to an internal gear or where a high gear ratio is desired.

- Internal Ring Gears: Internal ring gears, also known as internal annular gears, have teeth on the inner circumference of the gear. These gears mesh with an external gear or a pinion gear. Internal ring gears are frequently used in applications where the gear rotation needs to be transmitted to an external gear or where a compact gear assembly is required.

- Segmental Ring Gears: Segmental ring gears are ring gears that are divided into segments or sectors. Each segment has a portion of the gear’s circumference with teeth. These segments can be individually mounted or assembled together to form a complete ring gear. Segmental ring gears are used in applications where flexibility in gear installation or replacement is necessary, such as large-scale gear systems or machinery with limited access.

- Spur Ring Gears: Spur ring gears have straight teeth that are parallel to the gear’s axis of rotation. These gears offer simple and efficient operation with high gear ratios. Spur ring gears are commonly used in applications that require precise motion control, such as robotics, automotive transmissions, and industrial machinery.

- Helical Ring Gears: Helical ring gears have teeth with a helix angle. The helical teeth form a helical or spiral pattern around the gear’s circumference. Helical ring gears provide smoother and quieter operation compared to spur ring gears due to the gradual engagement of the teeth. They are often used in applications that demand high torque transmission, such as heavy machinery, marine propulsion systems, and power generation equipment.

- Bevel Ring Gears: Bevel ring gears have teeth that are conically shaped and intersect the gear’s axis of rotation. These gears are used in applications that require the transmission of motion and torque between shafts that are not parallel but intersect at an angle. Bevel ring gears are commonly found in automotive differentials, hand tools, and various industrial machinery.

- Planetary Ring Gears: Planetary ring gears are part of planetary gear systems, which consist of multiple gears arranged in a planetary configuration. The ring gear serves as the stationary outer gear, while other gears, such as sun gears and planet gears, revolve around it. Planetary ring gears are used in applications that require compact and efficient gear systems, such as automotive transmissions, robotics, and aerospace mechanisms.

The specific type of ring gear chosen for a particular application depends on factors such as load requirements, space limitations, gear ratios, operating conditions, and desired performance characteristics.

Can you provide examples of machinery that use ring gears?

Machinery in various industries utilize ring gears for different applications. Here are some examples of machinery that commonly use ring gears:

- Automotive Transmissions: Ring gears are an integral part of automotive transmissions. They are used in automatic transmissions, manual transmissions, and dual-clutch transmissions. Ring gears help transmit power from the engine to the wheels by engaging with the pinion gear or other associated gears.

- Industrial Gearboxes: Ring gears are extensively used in industrial gearboxes, which are employed in a wide range of applications. Gearboxes in industries such as manufacturing, mining, construction, and energy generation use ring gears to transmit power and control rotational speed. They provide torque multiplication and speed reduction or increase as required by the specific machinery.

- Wind Turbines: Ring gears are crucial components in wind turbines. They are used in the main gearbox to convert the rotational motion of the wind turbine blades into electrical power. The ring gear connects the rotor shaft to the generator, enabling the transmission and conversion of the mechanical energy into electrical energy.

- Rotary Tables: Rotary tables are used in machining operations to provide precise positioning and rotational movement. They are commonly found in milling machines, drilling machines, and machining centers. Ring gears are employed in the rotary tables to enable smooth and accurate rotation, allowing for precise machining and indexing of workpieces.

- Printing Presses: Printing presses, particularly those used for high-speed commercial printing, often incorporate ring gears. Ring gears help drive the paper feed mechanisms and synchronize the movement of various components, ensuring precise control and alignment during the printing process.

- Excavators and Earthmoving Equipment: Large construction machinery, such as excavators and earthmoving equipment, rely on ring gears for their hydraulic systems. Ring gears enable the rotation and control of the excavator’s superstructure, including the boom, arm, and bucket. They provide the necessary power and torque for efficient digging, lifting, and material handling.

- Conveyor Systems: Ring gears are utilized in conveyor systems, which are widely used in industries for material handling and transportation. They are often employed in large-scale conveyors to drive the pulleys and facilitate the movement of heavy loads along the conveyor belts. Ring gears ensure smooth and reliable operation of the conveyor systems.

- Robotics and Automation: Ring gears find applications in robotics and automation systems. They are used in robotic arms and joints to enable precise and controlled movement. Ring gears provide the necessary torque and rotational capabilities for various robotic applications, including assembly, pick-and-place operations, and material manipulation.

These examples represent just a few of the many machinery and equipment types that utilize ring gears. The versatility and reliability of ring gears make them essential components in various industries, where they play a crucial role in transmitting power, controlling movement, and ensuring efficient operation of machinery.

What are the applications of ring gears?

Ring gears, also known as annular gears or internal gears, have a wide range of applications across various industries and mechanical systems. Here’s a detailed explanation of the applications of ring gears:

Ring gears are commonly used in numerous applications where rotational motion, torque transmission, and load distribution are essential. The unique design and characteristics of ring gears make them suitable for a variety of mechanical systems. Here are some common applications of ring gears:

- Automotive Transmissions: Ring gears are extensively used in automotive transmissions, particularly in automatic and manual transmissions. They are part of the gear train that transfers rotational motion and torque from the engine to the wheels. Ring gears in automotive applications are typically large in size and designed to handle high torque loads.

- Differential Systems: Ring gears play a crucial role in differential systems found in vehicles. The differential assembly allows the wheels on an axle to rotate at different speeds while distributing torque evenly. Ring gears form an integral part of the differential assembly, enabling torque transfer and speed differentiation between the drive wheels.

- Planetary Gear Systems: Ring gears are a fundamental component in planetary gear systems, which are widely used in various applications. Planetary gear systems consist of a central sun gear, planet gears, and a ring gear. The ring gear serves as the outer ring that meshes with the planet gears and the sun gear. Planetary gear systems offer high gear ratios, compactness, and versatility, making them suitable for applications such as automotive transmissions, industrial machinery, and aerospace systems.

- Industrial Machinery: Ring gears find extensive use in industrial machinery for power transmission, motion control, and speed regulation. They are employed in equipment such as gearboxes, speed reducers, hoists, conveyors, and rotary tables. Ring gears enable efficient torque transmission, precise motion control, and load distribution in these industrial applications.

- Robotics and Automation: Ring gears are utilized in robotics and automation systems for precise motion control and synchronization. They can be found in robotic arms, automated assembly lines, CNC machines, and other robotic applications where accurate positioning and precise motion are critical. Ring gears provide the necessary torque transmission and gear reduction required for precise robotic movements.

- Power Generation: Ring gears are used in power generation equipment, such as wind turbines and hydroelectric generators. They form part of the gearboxes that convert the rotational motion of the turbine or generator rotor into electrical energy. Ring gears in power generation applications need to handle high torque loads, operate reliably, and provide efficient power transmission.

- Heavy Machinery and Construction Equipment: Ring gears are employed in heavy machinery and construction equipment, including excavators, cranes, mining equipment, and agricultural machinery. They facilitate the transmission of power and torque for various functions, such as lifting, digging, and material handling. Ring gears in these applications are designed to withstand high loads, rugged environments, and demanding operating conditions.

These are just a few examples of the applications of ring gears. Their versatility, load-carrying capacity, compact design, and ability to achieve high gear ratios make them suitable for a wide range of mechanical systems across industries.

The specific design, size, and material selection of ring gears may vary depending on the application requirements, operating conditions, and performance specifications.

editor by Dream 2024-04-30